Hurricane storm panels generally ship within 7-15 business days. These times are estimates based on prior orders and can change at any given time due to supply and demand. In slower times, many orders are completed sooner than these estimates whereas in busy times the orders may take longer than estimated. We can assure you we always work extremely hard on getting all orders completed as soon as possible.

ALL ORDERS ARE NOW 100% PROTECTED FROM BEING LOST, STOLEN, OR DAMAGED DURING SHIPMENT! DETAILS-RESTRICTIONS APPLY

Thank you for checking out our storm panels page! We hope you will quickly see that our website is vastly different (and we think vastly superior!) than all other hurricane shutters websites, including the big box stores! If you are looking to purchase hurricane storm shutters you have come to the right place.

Here's why:

-

You can actually order all of your storm panels, headers, footers, hardware, etc right on our site - in a matter of minutes - 24 hours a day, 7 days a week! No need to call us and wait for us to return your call. No need to set an appointment that might takes weeks!

-

We have the absolute lowest priced hurricane storm shutters on the planet!

-

We offer nine (9) different types of hurricane panels - including three different types of materials: aluminum hurricane shutter panels, clear polycarbonate panels, and galvanized steel hurricane shutter panels.

-

All of our storm shutters are code approved for all your hurricane protection needs.

-

Our hurricane shutters are made in the USA and can be shipped anywhere in the world - straight to your front door!

-

We do not charge extra for custom sizes and have every length from 12 inches up to 150 inches - and every inch in between! Even half panels! And white panels!

-

We have every single size hurricane shutter! No waiting and paying extra for special orders and sizes. Whatever size storm shutter you need - we will make it especially for you - with no custom upcharges! You can even order odd sizes, like 36.25", 65.50" or 78.75" - all priced at the same price per foot.

-

We encourage you to go to your local big box store and look online at our competitors. As you will see, most of our competitors do not disclose their prices on their website. They want you to fill out a form or call them. They hide their prices because they know if they show them on their website you won't buy from them! They are way too high!

-

Our prices are displayed prominently right on our website - we have nothing to hide! Our prices are as much as 50% cheaper than our competitors! We are confident you will see that we beat everybody!

Our website offers two easy ways to order storm panels:

1. Using our Instant Quote Calculator which will you give you a price for each opening - including the number of panels, headers, footers, etc. It will even tell you the number of panels and the lengths you need!

2. Ala Carte - If you know what you want, you can order panels individually. Just select the type of panel you want and the length you need and add it to the shopping cart - it's that easy!

How to use our Instant Price Calculator

Step 1: Select the type of opening you are looking to protect . Select from: Window, Door/Sliding Glass Door, Garage Door, Covered Porch/Patio. If you are looking to cover a type of opening other than those provided, select the type most similar.

Step 2: Select the construction material around your opening. Select from: Concrete, Wood Frame, Wood Frame with Stucco, or Brick. If your material around your opening is something other than those provided, select the type most similar.

Step 3: Enter the width and height of your opening. Make sure you are measuring from the outside of the opening - not inside the house for example. Also make sure you are measuring the rough opening - do not measure to the outside of any trim - only the rough opening. If you have an obstruction, like a window sill, it is often necessary to include that obstruction as part of the window measurement. This will allow the Finished Length of the Panel to extend far enough past the obstruction.

Important Note: Steps 1 through 3 are used to determine the total length of the hurricane panels you need and the number of hurricane panels you need. Concrete homes generally require a longer shutter to maintain a proper "edge distance" from the edge of the concrete so they concrete doesn't "blow out" when installing anchors. Wood Frame, Wood Frame with Stucco, or Brick homes generally require a shorter panel as the panels need to line up with the structural studs of the opening. The studs around each opening only go so far and then it generally becomes hollow. After your selections, our website will display the "Finished Length of Panel" of the suggested panels and the "Total Panel Coverage" (Which is the width of the panels nested together). We strongly recommend you re-measure your opening, taking into account this finished length of the panel and the total panel coverage to make certain they will work for your application.

Step 4: Select which shutter you are interested in. You can use our handy Chart below for some quick information or click on each shutter type in the chart for more details. You can even change from shutter to shutter and the price will be updated immediately! (You will need to select an option for Step 5 when updating the prices)

|

|

|

|

|

|

|

|

|

|

|

|

Material |

Steel |

Steel |

Aluminum |

Polycarbonate |

Steel |

Aluminum |

Steel |

Aluminum |

Polycarbonate |

|

Shutter Height |

2 Inches |

2 Inches |

2 Inches |

2 Inches |

2.25 Inches |

2.25 Inches |

2.25 Inches |

2.25 Inches |

2.25 Inches |

|

Shutter Width |

14.375” Wide |

14.375” Wide |

14.375” Wide |

14.375” Wide |

15” Wide |

15” Wide |

15” Wide |

15” Wide |

15” Wide |

|

Shutter Length |

12” to 150” |

12” to 150” |

12” to 150” |

12” to 150” |

12” to 150” |

12” to 150” |

12” to 150” |

12” to 150” |

12” to 150” |

|

Weight (per Ft) |

1.64 lbs/Ft |

1.64 Lbs/Ft |

1.12 Lbs/Ft |

1.00 Lbs/Ft |

1.89 Lbs/Ft |

1.25 Lbs/Ft |

2 Lbs/Ft |

1.28 Lbs/Ft |

1.00 Lbs per Ft |

|

Available in Full / Half Panels |

Full & Half Panels |

Full Panels Only |

Full & Half Panels |

Full & Half Panels |

Full & Half Panels |

Full Panels Only |

Full & Half Panels |

Full & Half Panels |

Full Panels Only |

|

Product Approvals |

FBC (Non-HVHZ) |

FBC (HVHZ), FBC (Non-HVHZ) |

FBC (HVHZ), FBC (Non-HVHZ), IBC, IRC |

FBC (Non-HVHZ), FBC (HVHZ), TDI, IBC, IRC, Miami-Dade |

FBC (Non-HVHZ), TDI |

FBC (Non-HVHZ) |

FBC (HVHZ) |

FBC (Non-HVHZ), FBC (HVHZ), TDI, IBC, IRC, Miami-Dade |

FBC (Non-HVHZ), TDI |

Product Approval Codes FBC: Florida Building Code; HVHZ: High Velocity Hurricane Zones (Miami-Dade and Broward Counties); Non-HVHZ: Non High Velocity Hurricane Zones (All other Counties); TDI: Texas Department of Insurance Standards; IBC: International Building Code; IRC: International Residential Code.

Step 5: Select whether you are going to install the panels vertically or horizontally. Vertically is the most common, however, if you have an obstruction above or below your opening (like a window sill) you can choose horizontally. You can also compare prices between the two to see which option is cheaper!

Step 6/7: You have the option of installing your shutters with a Header bracket (a track above your opening), a Footer bracket (a track below your opening), any combination of the two (both a header and a footer, a header but no footer, a footer but no header) or with no brackets (called "Direct Mount"). If you selected "Horizontally" in Step 5, the wording will be changed to just "mounting bracket". Similar to the other steps, the price changes instantly depending on your selection!

IMPORTANT: Due to the extreme cost of shipping long lengths of headers and footers, any headers or footers over 120" to be shipped will be cut in half. They can easily be butted back together during installation. No headers/footers will be shipped that are longer than 120". Please be aware of this when ordering.

Types of Headers/Footers (Click on each option to be taken to the individual page for more information):

- H-Header: This is the most common header bracket to be attached to the wall above an opening. An H-Header allows the panel to slide into the channel without having to be secured with bolts at the top. Often times, the panels can be inserted into the H-Header from the ground without the use of a ladder - making it an extremely popular option.

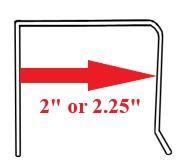

We offer two types of H-Header - a 2" H-Header for 2" hurricane panels and a 2.25" H-Header for 2.25" panels. Our Instant Price Calculator will automatically select the correct one based on your panel selection in Step 4.

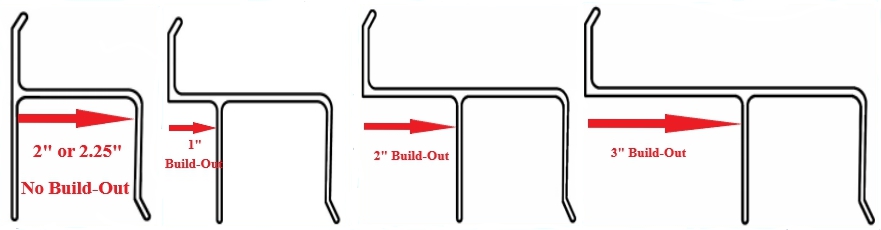

Additionally, we offer H-Headers with four (4) options: No build-out, 1" build-out, 2" build-out, and 3" build-out. A "build-out" refers to how far the header channel is pushed out from the wall. Normally, no build-out is needed, however, if you have a window sill, window trim, or any other type of obstruction, you may need a build-out option. Measure how far the obstruction sticks out from the wall to determine the build-out size you need. For instance, if you have a window sill that sticks out 1.5" from the wall, you would need a 2" build out option since the 2" build-out will push out the header channel 2" from the wall allowing it to go over the window sill.

- U-Header: A U-Header is similar to an H-Header, however, it attaches to the ceiling - not the wall. Panels slip up into a U-Header which also allows the panels not to be secured with bolts at the top and without the need for a ladder.

We offer two types of U-Header - a 2" U-Header for 2" hurricane panels and a 2.25" U-Header for 2.25" panels. Our Instant Price Calculator will automatically select the correct one based on your panel selection in Step 4.

- Flat F-Track: A Flat F-Track or stud-less F-Track can be used above an opening, however it is primarily used below an opening or on the sides of an opening. F-Tracks can only be attached to a wall. A no build-out F-Track has a much smaller profile than the H-Header or U-Header as it only sticks out approximately 1/2" from the wall. F-tracks use removable F-Track bolts (found here) which slide in and out of the track. When not in use the F-Tracks bolts should be removed and stored separately.

An F-track is universal - it can be used for 2" panels, 2.25" panels, or any other type panel as long as the panels have holes.

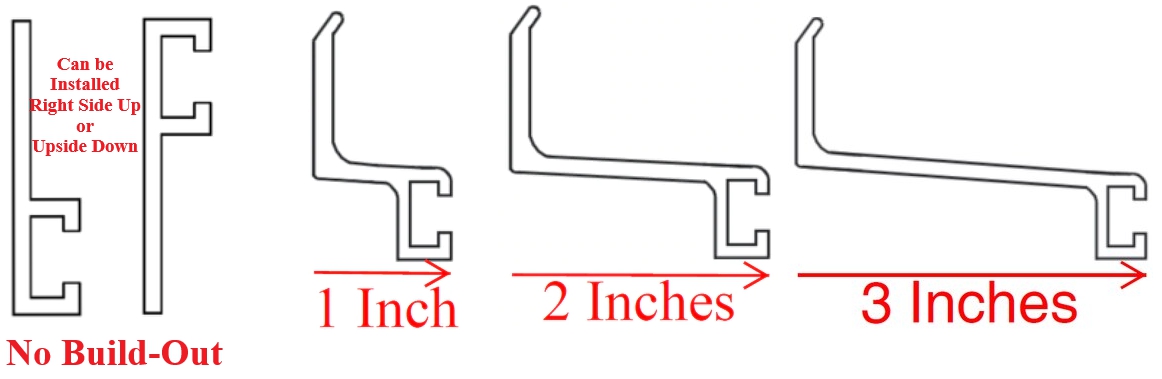

F-Tracks are available in four (4) options: No build-out, 1" build-out, 2" build-out, and 3" build-out. A "build-out" refers to how far the F-Track is pushed out from the wall. Normally, no build-out is needed, however, if you have a window sill, window trim, or any other type of obstruction, you may need a build-out option. Measure how far the obstruction sticks out from the wall to determine the build-out size you need. For instance, if you have a window sill that sticks out 0.5" from the wall, you would need a 1" build out option since the 1" build-out will push out the F-Track 1" from the wall allowing it to go over the window sill. Usually, but not always, if you need an H-Header with a 2" build-out above the opening you would need a 2" build-out F-Track as well. To be installed properly, the panels need to be as straight vertical (or horizontal) as possible or the panels will not fit in the H-Header (if used).

- Studded Angle with Studs Every 6 Inches: A studded angle, along with the F-Track, is the most common track used below an opening to secure hurricane panels. A studded angle is "L" shaped (2" vertical and 2" horizontal) with stainless steel studs permanently installed every 6 inches on the vertical side. The studs face "inward" over the horizontal side of the bracket. Because the studs are permanently installed, using a studded angle is among the fastest and easiest ways to install hurricane shutters when a storm is approaching. A studded angle can be attached to a wall with anchors on the vertical side or to the floor with anchors on the horizontal side. Often times, studded angles are installed to be "removable" - in front of a garage or in front of a sliding glass door for example.

- Low Profile Studded Angle with Studs Every 6 Inches: A low profile studded angle is similar to a regular studded angle in its "L" shape, however, it only measures 1.75" on the vertical side by .632" on the horizontal side. The stainless steel studs are also permanently installed every 6 inches on the vertical side and face "inward" over the horizontal side of the bracket. Because the studs are permanently installed, using a low profile studded angle (or regular studded angle) is among the fastest and easiest ways to install hurricane shutters when a storm is approaching. Due to there only being .632" on the horizontal side, a low-profile studded angle can be only be attached to a wall and cannot be attached to the floor.

- Reverse Studded Angle with Studs Every 6 Inches: A reverse studded angle is the same as the regular studded angle, however, the stainless steel studs face "outward". A reverse studded angle is also "L" shaped (2" vertical and 2" horizontal) with stainless steel studs permanently installed every 6 inches on the vertical side. Because the stainless steel studs face outward, a reverse studded angle cannot be attached to a wall and can only be attached to the floor via anchors on the horizontal side. Reverse studded angles can also be installed to be "removable".

- F-Track Studless Angle: An F-Track Studless Angle is also "L" shaped and measures 1-5/8" on the vertical side and 2" on the horizontal side. It has similarities to both the studded angle and the Flat F-Track - it is shaped like the studded angle but allows for removable studs like the F-Track. F-Track studless angles can be attached to either the wall or the floor and can also be installed to be "removable". The channel for the F-Track bolts faces "inward" over the horizontal side.

- Reverse F-Track Studless Angle: A Reverse F-Track Studless Angle is virtually the same as the regular F-Track Studless Angle, however its channel for the F-Track bolts faces "outward" and it can only be installed on the floor. The Reverse F-Track Studless Angle is also "L" shaped, allows for removable studs, and measures 2" on the vertical side and 2" on the horizontal side. It can also be installed to be "removable" if desired.

IMPORTANT: Due to the extreme cost of shipping long lengths of headers and footers, any headers and footers over 120" to be shipped will be cut in half. They can easily be butted back together during installation. No headers/footers will be shipped that are longer than 120". Please be aware of this when ordering.

Step 6.1/7.1: Select the color of the brackets you would like. Most options come in two colors - white or bronze. Some brackets, however, are not offered in all colors and some brackets are additionally offered in a "mill finish" color (similar to the color of the storm panels.

Step 6.2/7.2: Select whether you would like us to pre-drill your headers. This is a huge time-saving feature we offer! If selected, we will pre-drill your brackets so that they are ready to be installed immediately upon delivery. Choose from three (3) options: every 6 inches, every 9 inches, or every 12 inches. Check with your local ordinance or select every 6 inches for maximum holding power!

Step 8: Use this space to let us know of you have any additional comments or questions that might need to be addressed.

Hurricane Shutters and Storm Shutters Get Instant Pricing